RS Refractory Factory

RS Refractory has established complete quality system and implements whole staff and whole process quality control. All kinds of Refractory Fire Bricks, strictly according to the ISO9001 standard, are export to Japanese, Indonesia, Iran, Kazakhstan, and etc.

Home

Hot-sale product

About Us

Rongsheng is a manufacturer of refractories, heat resistant products and high temperature insulation materials which follows the tradition of refractory and heat resistant manufacturing in Xinmi, China, since 2003.

Our products include fire bricks, insulation bricks, refractory castable/cements/mortars, plastic mouldables refractories, zircon refractory products, acid resistant cements and refractory castables for use in industries including steel plants, heat and power stations, foundries both ferrous and non-ferrous, cement producers, lime producers, glass works, ceramics, coke plants, incinerators, renewable energy, chemical works, sugar refineries and petrochemical industry.

Light weight fire clay brick is a kind of high temperature adiabatic refractory material. It is made of refractory clay and is made of clay, which can be used as the binding agent of clay, and the added amount of combustible or foaming agent can be obtained by firing. Light weight fire clay brick is used for the insulation of the heating layer of the gas producer. The temperature in the 1200-1400 ℃. Ingredients are mixed with water made of plastic material or mud, mud with extrusion or pouring shape, 1250-1350 ℃ after dry burning oxidation atmosphere. The volume density of commonly used clay bricks is 0.75-1.2 g/cm3. In reality, more than 1.0, Light weight fire clay brick insulation brick index is the most concise method to judge its performance.

1.Adopt insulation measure for heating equipment, which should not affect the service life of whole refractory lining body.

2.It is reasonable to adopt thermal insulation in large area for high temperature kiln that keep continuous working, which will reduce the heat loss. But for less special position, such as roof of open-hearth furnace, when the thermal insulation result the lining body rising temperature which cause the heat loss more than without the thermal insulation. Then there is no need to adopt the method of thermal insulation. So according to the thermal storage and heat loss to calculate and decide if need to adopt heat insulation measures.

3.As the Lightweight Insulating Fire Brick has higher apparent porosity, when use Lightweight Insulating Fire Brick that cannot bear overload. And also avoid contacting molten metal, molten slag and high temperature furnace lining.

4.Lightweight Insulating Fire Brick has low strength. When laying Lightweight Insulating Fire Brick, need to layout the brickwork joint and expansive joint rightly to avoid breaking the lining body due to expansion. Lightweight Insulating Fire Brick should not suffer the strong mechanical shock, hit and abrasion.

5.Lightweight Insulating Fire Brick has the large reheating linear shrinkage. Its maximum service temperature is lower than 100℃ that should definitely not higher than the allowable tempeature.

Light Weight Fire Clay Brick Uses

ight weight fire clay brick is widely used in metallurgical building materials chemical petroleum machinery manufacturing silicate power and other industrial fields, used in hot air furnace.As a low price refractory material, the light weight high alumina bricks are applied in Furnace Lining And Insulation Layers,Ceramic Tunnel Kiln,Roller Kiln,Shuttle Kiln,Heating Furnace & Coking Furnace In Iron And Steel Industry,Other Thermal Equipment & Heat Treatment Lining.

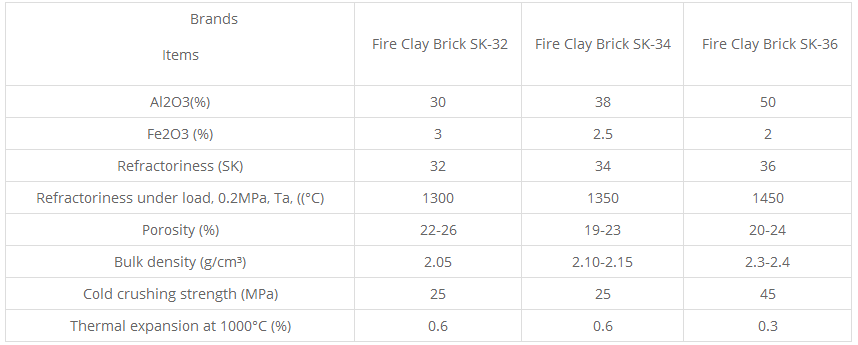

Light Weight Fire Clay Brick Specifications

Light Weight Fire Clay Brick Supplier

Zhengzhou Rongsheng Kiln Refractory Material Co., Ltd is an enterprise specializes in producing and selling refractory materials.We have twenty-year’s practice in producing refractory materials and four associated factories with one trading company.welcome to buy light weight fire clay brick at Rongsheng Kiln Refractory Co.,Ltd. and enjoy our high quality service. Please leave your massage and we will be in contact as soon as possible.

News and Media

Products

- Home

- Refractory Brick

- Acid Proof Brick

- Alkali Resistant Bricks

- alumina refractory brick

- China Zirconium Silicate Factory And Manufacturers | Rongsheng

- Clay Fire Brick

- Corundum Fire Brick

- Fire Clay Brick

- Graphite Electrode

- Light Weight Fire Clay Brick

- Light Weight High Alumina Brick

- Magnesia Fire Brick

- Mullite Fire Brick

- Silica Refractory Brick

- Special Shaped Fire Brick

- Spinel Fire Brick

- Zircon Fire Brick

- Refractory Brick

- Insulating Brick

- insulation

- Insulation Refractory

- Refractory Castable